Surface treatments are used to improve the surface of a manufactured item. Reasons may be to improve corrosion protection, wear resistance and friction control. Surface treatments typically are removing material, adding material or chemically altering the surface. Surface treatments are widely used in most industries to provide improved surface properties of a component. The surface of a product, component or construction is of vital importance to its appearance, technical durability, performance and functionality (wear, corrosion, adhesion, etc.). In fact, many surface treatment technologies are an essential part of the production process.

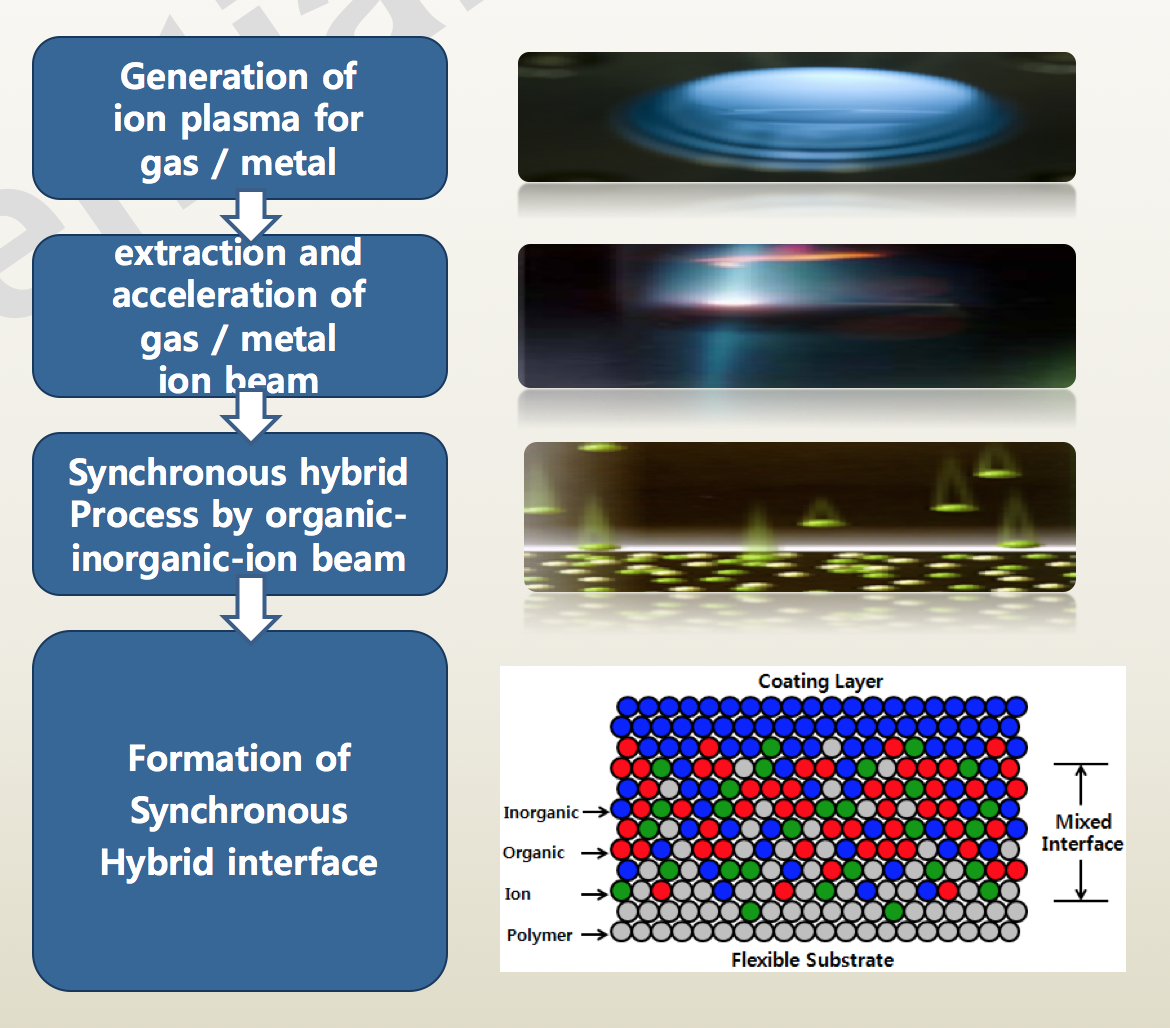

ESM is a company that has “Surface treatment technology through ion beam”. The characteristic for surface process using ion beam has no modification of object because of the low processing, which is less than 200 degrees. It is applicable as the final progress of end products, local process is possible, and is able to improve corrosion resistance, oxidation resistance, and optical characteristic.

This technology can be used in various fields. Flexible OLED encapsulation is a typical example. When the surface treatment is performed using the ion beam, it is possible to eliminate the disadvantages of the peeling phenomenon that has occurred in the past, and it is advantageous that the complicated sealing process can be simultaneously performed in one equipment. This can save a lot of time and money.

It can also be applied to architectural film, which can reduce the heating cost of the building and prevent the internal discoloration, high-k dielectric semiconductor process to obtain high permittivity, semiconductor transport tray to prevent static electricity, and functional packaging material film and container to produce antimicrobial effect and deterioration by ultraviolet ray and gas permeation. In addition, it can be applied to polymer membrane film, portable terminal case, mesoporous film (flexible organic solar cell), vehicle and other painting process, and so on.

On this introduction of ESM’s ion-beam surface treatment technology, it can achieve cost reduction and productivity improvement by simplifying the process and improve the quality of the product. In the future, this technology can be applied to various industries such as automobiles, home appliances, semiconductors, displays, photovoltaics, and packaging materials, not just for specific industries. This process simplification can provide convenience for producers and provide consumers with highest quality products at a minimum cost.

▲ ESM

▲ Brand Name: Flexen

▲ CEO : Seung-gwang Lee

▲ www.flexen.co.kr

▲ E-mail : gksmfrk@daum.net

▲ T : +82 31-287-6361

Dean Lee, Irene Kim

K-Herald Korea

(Los Angeles Times Advertising Supplement)